Not known Factual Statements About gearbox cvt

Not known Factual Statements About gearbox cvt

Blog Article

V-belts are chosen Should the belt is product of rubber. V-belts get their title from the fact that the belts bear a V-shaped cross segment, which raises the frictional grip of the belt.

Hydrostatic CVTs Both of those the pulley-and-V-belt CVT as well as the toroidal CVT are samples of frictional CVTs, which function by varying the radius with the Call stage amongst two rotating objects. There is another type of CVT, often called a hydrostatic CVT, that employs variable-displacement pumps to change the fluid movement into hydrostatic motors.

CVTs are Similarly economical on hills. There is not any "gear looking," since the CVT cycles steplessly right down to a gear ratio suitable for the driving ailments. A standard automated transmission shifts back and forth attempting to discover the ideal gear, which can be much considerably less economical.

Should you be searching for a new commuter car or truck or crossover, you may have observed that the product you favor comes with a continually variable transmission (CVT).

Once you action over the gas pedal of a vehicle using a continuously variable transmission, you discover the primary difference quickly. The engine revs up towards the rpms at which it generates by far the most electricity, after which it stays there. However the car does not react straight away. Then, a instant afterwards, the transmission kicks in, accelerating the vehicle slowly, steadily and without any shifts.

A CVT or Consistently Variable Transmission is definitely an automated, solitary velocity, and gearless transmission that could shift by way of an infinite range of gear ratios.

[example necessary] In mowing or harvesting operations, the CVT permits the ahead speed in the tools to generally be modified independently in the motor velocity; this allows the operator to sluggish or accelerate as wanted to support variations during the thickness of the crop.

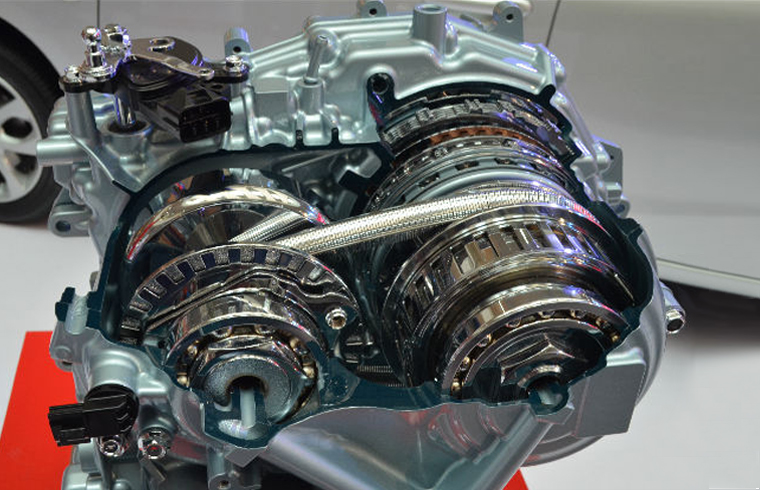

By comparison, a consistently variable transmission can be a research in simplicity. Most CVTs have only 3 simple components:

A consistently variable transmission procedure is really a sort of automated transmission during which an arrangement of pulleys and belts manufactured it probable for just a drive to achieve n-quantity of continuous gear ratios in a array (depends upon the design).

The drive ratio is usually established to infinity (i.e. a stationary output disk) by relocating the output disk to the center of your enter disk. The output path will also be reversed by transferring the output disk past the middle in the input disk. The transmission on early Plymouth locomotives labored in this way, though on tractors making use of friction disks, the number of reverse speeds was usually restricted.[29]

HowStuffWorks The variable-diameter pulleys are the guts of a CVT. Just about every pulley is manufactured from two twenty-degree cones experiencing each other. A belt rides from the groove in between The 2 cones.

C’est pourquoi on parle de « variation keep on » et d’un nombre de rapports « à l’infini » (certaines personnes affirment à tort que ce kind de transmission ne comporte qu’une seule vitesse).

CVTs could use hydraulic tension, centrifugal power or spring pressure to create the power important to modify the pulley halves.

It’s like anything else that’s multi-intent; you purchase a camera lens that can do 18mm to 300mm and it’ll under no circumstances be nearly as good as being a two lenses that just do eighteen and 300mm respectively. There’s all kinds terus ke sana of technologies that will help engines operate more than rev ranges such as variable valve timing, but Even so the fundamental problem stays.